In August 2025, a shipment of 68 Aladdin 20W linear laser lights was dispatched to South Korea for deployment in a modern smart warehousing center. This was no ordinary purchase, but rather the most solid vote of confidence placed by an international logistics equipment giant after months of rigorous three-phase trials. Linear laser lights are now becoming indispensable tools in the advancement of industrial precision.

I、The Client’s Challenge:

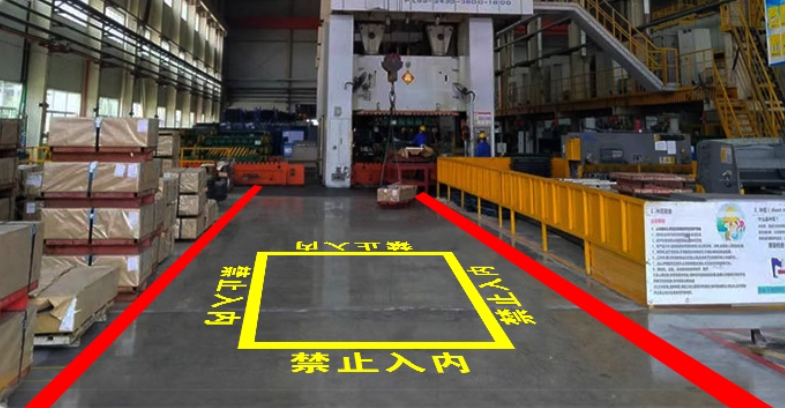

Efficiency and Precision Bottlenecks in Traditional Marking Before providing solutions for Korean clients, they faced the same challenges as many factories and warehouses worldwide: how to quickly, accurately, and permanently mark shelf areas on the ground, identify AGV routes, and secure access paths. In the past, workers had to apply tape, which was prone to wear and tear, requiring manual removal and reapplication. A single precise marking line could take half a day, often resulting in errors. These minor inaccuracies would amplify in large-scale warehouse systems, directly reducing space utilization, picking efficiency, and even posing operational safety risks. What the client needed was a marking solution that could completely surpass traditional methods, offering a one-time, permanent fix for precision

II、Precise Breakthrough: From 10W to 20W, Three Samples Witness the Hard Power of “Optical Micro-carving”

Given our clients’ high standards, we understand that only top-tier products can withstand rigorous scrutiny. Their testing process is exceptionally meticulous:

1、Initial Test (10W Sample): The customer first tested a 10W model to evaluate basic performance and linear uniformity. Feedback indicated clear lighting, though brightness could be improved under the warehouse’s specific lighting conditions.

2、Performance Upgrade (20W Sample): Based on initial feedback, we recommend upgrading to the 20W model. The enhanced power ensures laser lines remain clearly visible in bright environments, with customers praising both brightness and stability.

3、Small-scale field test (8 units of 20W samples): The real challenge began. The client placed an order for 8 units at once, deploying them in a limited scope within their warehouse’s actual operational environment. This test evaluated the product’s long-term stability, interference resistance, and consistency under complex conditions. The Aladdin linear laser lamp successfully passed the test, thanks to its precision optical design (ensuring uniform and straight lines throughout), robust heat-dissipating casing, and industrial-grade durability

III、The Fruit of Trust:68 Sets of Orders Open a New Chapter of Intelligent Warehousing

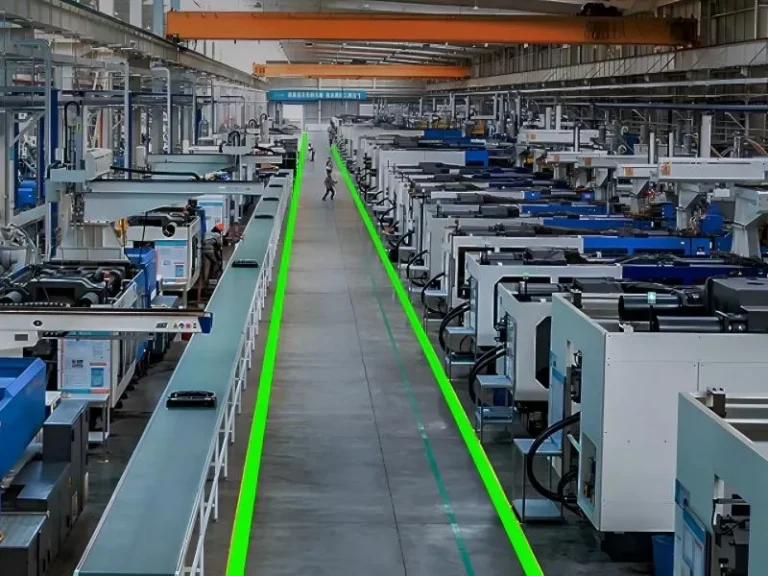

Through two performance fine-tuning sessions, one full-scale deployment, and three sample trials, Aladdin established a complete product validation cycle. The client was ultimately convinced that its linear laser lights were not just ordinary lighting fixtures, but precision infrastructure designed to enhance warehouse operational efficiency. This natural progression culminated in August this year with the formal order for 68 sets of 20W linear laser lights, marking Aladdin’s successful integration into the client’s intelligent upgrade blueprint. These laser lights will serve as invisible rulers, providing 24/7 navigation for shelf zoning and automated guided vehicles (AGVs), replacing repetitive manual marking with perpetual straight-line guidance.

IV. The Revelation of Aladdin:

Light is also the Core ProductivityTruly efficient production hinges on precision and reliability. The one-line laser lamp transcends mere straight-line output—it delegates repetitive, high-demand tasks to intelligent, stable tools, freeing human focus for more creative endeavors. The evolution from ‘manufacturing’ to ‘smart manufacturing’ is built upon countless such details. That silent, straight laser line is more than just a beam of light; it embodies the Aladdin team’s unwavering commitment to quality and their relentless pursuit of industrial efficiency.