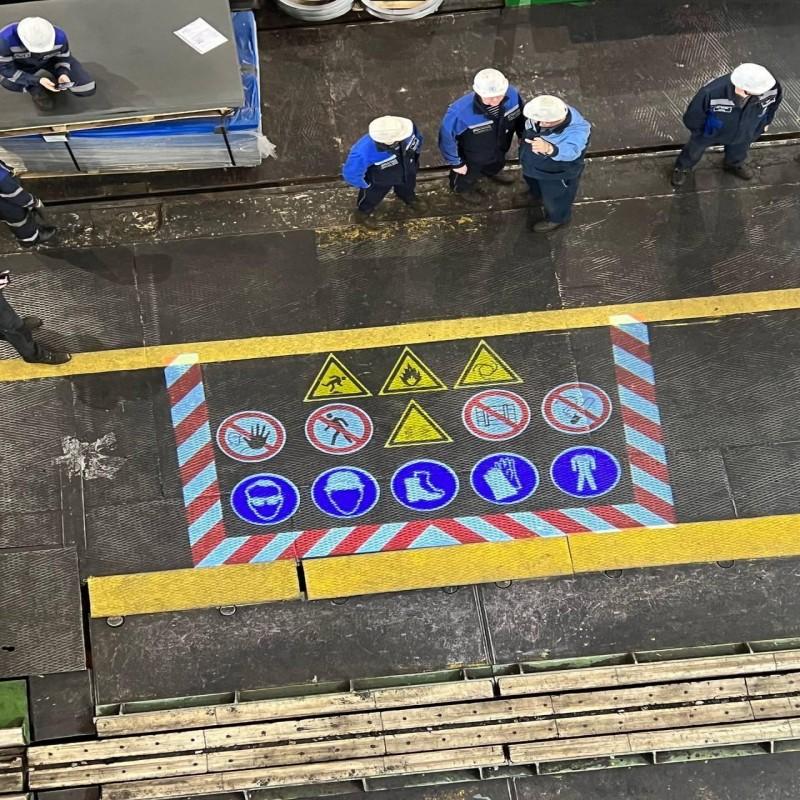

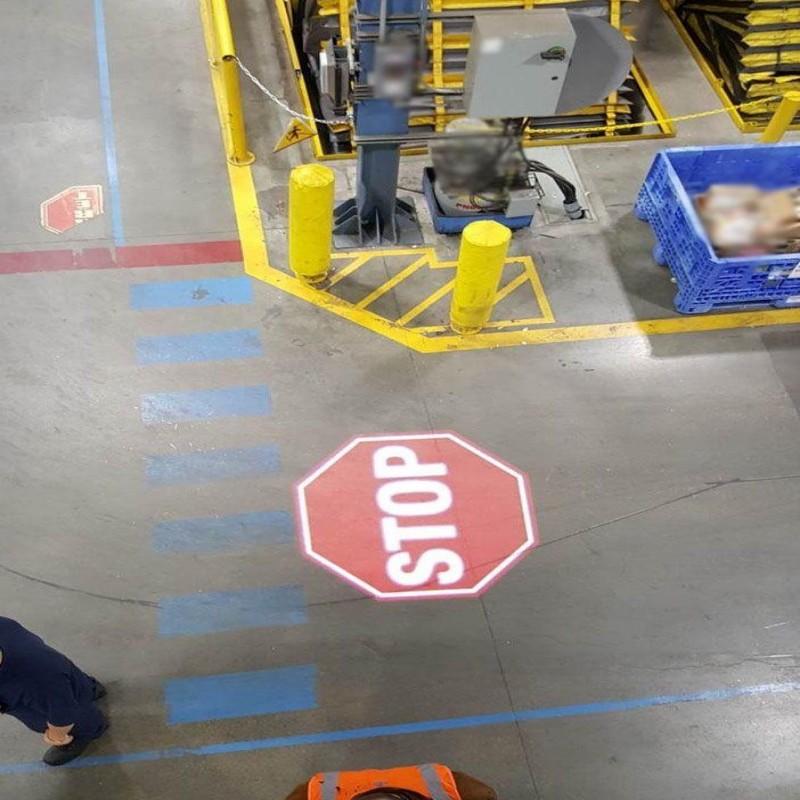

Today in industrial environments, large equipment like cranes and overhead traveling cranes are indispensable, but their operation comes with potential safety risks. Industrial projector lights play a crucial role in enhancing visibility, marking warning zones, and guiding safe workflows—making proper installation essential for maximizing their effectiveness. Many teams overcomplicate the process, but with these 3 core steps, you can install your industrial projector safely and efficiently, no specialized expertise required.

Step 1: Verify Voltage Compatibility and Complete Safe Wiring

Voltage matching is the foundation of reliable and safe projector operation. Begin by reviewing the product manual to confirm the projector’s rated voltage range. Most high-quality industrial projector lights offer customizable voltage options, allowing seamless adaptation to your site’s existing power supply—ideal for diverse industrial setups.

Before any wiring work, always cut off power to the relevant circuits to eliminate electric shock hazards. Use professional electrical tools to test the on-site voltage, ensuring it aligns with the projector’s rated voltage or customized range. Next, follow the manufacturer’s wiring instructions precisely: strip wire ends carefully, make secure connections, and ensure all insulation layers are intact to prevent short circuits or leakage. After wiring, conduct a brief power-on test: if the projector fails to start or shows irregularities, immediately shut off power and inspect connections for loose wires or mismatched voltage.

Step 2: Mount the Base Securely for Long-Term Stability

Industrial sites often involve vibrations from equipment operation, so a stable base is non-negotiable to prevent the projector from shifting, falling, or compromising projection quality over time.

Fortunately, industrial projector lights come with a full set of installation accessories—no extra purchases needed. Start by selecting an optimal mounting location: it should be flat, sturdy, and unobstructed to ensure the projection covers the target work area (e.g., crane operation zones, safety walkways). Attach the base firmly to the surface using the included bolts, tightening them with tools to eliminate any looseness. For high-vibration environments (e.g., near heavy machinery), add shock-absorbing gaskets between the base and mounting surface to further reduce movement and extend the projector’s lifespan.

Step 3: Adjust Angle and Clarity for Optimal Performance

Once the base is secured, fine-tuning the projection settings ensures the projector lights delivers clear, targeted guidance for your team.

Industrial projectors feature 360-degree angle adjustment, offering flexibility to align the projection with your specific needs—whether horizontal, vertical, or angled. Consider the layout of your work area, equipment movement paths, and operator viewing positions: aim to cast projections on critical spots like warning boundaries, equipment operation markers, or emergency exits. After setting the desired angle, lock it in place with the adjustment knob to prevent unintended shifts during use.

Next, adjust the clarity by rotating the projector’s lens ring. Observe the projection from typical operator distances, fine-tuning until text, logos, or symbols are sharp and free of blurriness or ghosting. Take time to test different viewing angles to ensure the projection remains clear for all team members involved in the workflow.

With these three steps, your industrial projector installation is complete. The process is designed to be straightforward, allowing on-site teams to handle it without external support. A properly installed industrial projector not only enhances visibility but also reinforces safety protocols, reduces the risk of accidents, and supports smooth, compliant production operations. Invest a little time in correct installation, and reap the long-term benefits of a safer, more efficient workplace.